Metallurgical Insight

From Fracture to Confidence.

What an unexpected performance issue taught us about steel microstructure, heat treatment, and the power of going deeper.

Imagine being the manufacturer of industrial parts designed to withstand harsh conditions, only to hear that they are failing prematurely. Fractured parts, downed equipment, and steel fragments are now threatening the work landscape.

This is precisely what one of Worthington Steel's long-time customers, a trusted manufacturer, was facing when they reached out with a growing concern: steel that had worked perfectly for over a decade was suddenly breaking under pressure in a more demanding application.

It was not just a product issue. It was a partnership moment. This story highlights how metallurgy, collaboration, and root-cause thinking make all the difference.

This article will walk you through the following:

- When a Trusted Process Starts to Break

- Uncovering a Hidden Vulnerability

- Why Microstructure Matters in Performance Steel

- Heat Treatment Was Not Enough with Existing Equipment

- The Breakthrough: Microstructure through Collaboration

- Lab-Driven Confidence: How Testing Guided the Path Forward

- Commercial Follow-Through: A Role for Sales and Support

- The Advantage of a Domestic Mill Partnership

- Why Location Matters: From Mill to Field

- Partnership Over Transaction: A Cultural Value

- Lessons for the Industry: Early Engagement, Real Impact

- From Fracture to Confidence

"We were making similar parts for many years with no issues."

- Paul Pfeifer, Technical Service Manager & Metallurgist

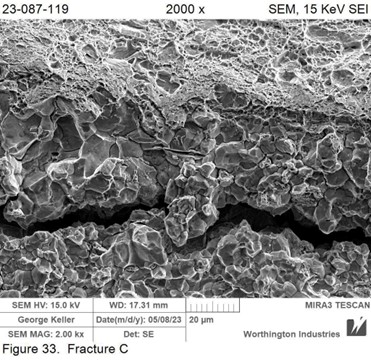

Caption: The fracture surface shows a mixed-mode fracture morphology.

When a Trusted Process Starts to Break

When Paul Pfeifer, a Technical Service Manager and Metallurgist at Worthington Steel, first got the call, he was surprised. "We were making similar parts for many years with no issues," he explained. The customer had explained their use of the steel from previous designs to a new application. Since the steel grade has performed reliably for years, and the initial components had passed durability tests, both teams felt confident moving forward.

However, as production scaled up, new variables in the manufacturing process and field performance revealed unexpected differences, highlighting that this application brought different demands. That shift in application was enough to expose a previously unseen vulnerability in the steel.

Worthington immediately acquired failed parts for testing. "We have what I'd consider a world-class lab," said Pfeifer, "and the sooner we get samples, the sooner we can isolate what's happening."

The sense of urgency was real. Time was of the essence.

Uncovering a Hidden Vulnerability

Once the laboratory had the sample parts, metallurgical testing began. Under the microscope, things got clearer and more complex. The failures were not random. They were following faint "rivers" in the steel's internal structure. What stood out at very high magnifications was the lack of a homogenous microstructure, notably the presence of ferrite, something that typically would have dissolved during subsequent heat treatment.

"We have what I'd consider a world-class lab and the sooner we get samples, the sooner we can isolate what's happening."

- Paul Pfeifer, Technical Service Manager & Metallurgist

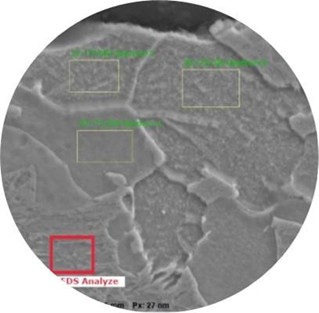

Caption: SEM picture of the fracture surface, in the microscope.

Ferrite is a crystalline phase of steel. While useful in certain applications, in this case, it was acting as a soft fracture path through the material, creating the perfect environment for failures under real-world pressure.

"These bands became fracture initiation sites," said Pfeifer. "Once the part hit something hard, it could literally grenade."

In this application, that meant broken components, added labor, potential equipment damage, and unhappy customers downstream. But more importantly, it meant a puzzle that needed solving fast.

"These bands became fracture initiation sites and once the part hit something hard, it literally grenade."

- Paul Pfeifer, Technical Service Manager & Metallurgist

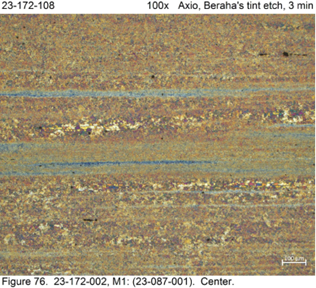

Caption: 100x picture of the microstructure showing the ferrite banding.

Why Microstructure Matters in Performance Steel

To understand why the microstructure was such a problem, it helps to look at how steel behaves under stress. Steel's strength is heavily influenced by its carbon and is inherently soft. If too much of it remains in a heat-treated part, it becomes the path of least resistance, exactly where cracks begin.

In high-impact applications, softness is not just a flaw but a failure point. Recognizing this, the team focused on the steel's response to heat treatment and what might prevent those ferrite bands from transforming properly. Ideally, the material would have undergone a longer heat treatment soak, around one hour per inch of thickness, to allow the ferrite to dissolve into the solution thoroughly.

However, the customer's furnace had cycle time limitations, making it challenging to reach that threshold without modifying the process. In this case, the combination of the incoming microstructure and constrained heat treatment played a critical role in performance.

"Heat treating steel is all about time at temperature and ferrite takes a longer time and/or higher temperature to dissolve."

- Paul Pfeifer, Technical Service Manager & Metallurgist

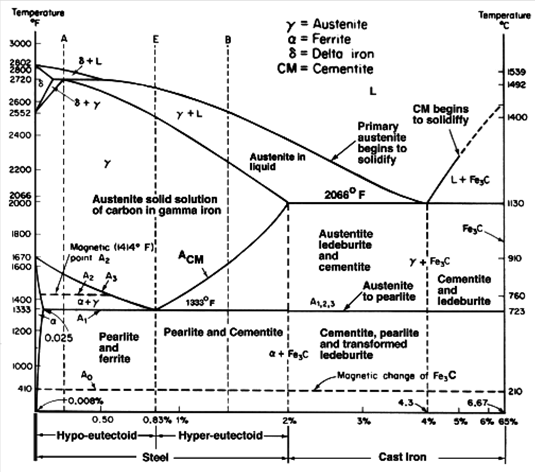

Caption: SEM photo of cross-section showing the different phases of steel present.

Heat Treatment Was Not Enough with Existing Equipment

The customer had already tried modifying their heat treatment process. However, their furnace setup offered limited control over cycle time. They ran at about half the ideal soak time, which meant the steel never fully transitioned into the desired phase.

"Heat treating steel is all about time at temperature," Pfeifer explained. "And ferrite takes a longer time and/or a higher temperature to dissolve. Without enough soak time or temperature, it just does not transition."

Even smaller changes in cycle time can drastically alter the outcome of a material as complex as steel. However, in this case, the equipment constraints meant the customer could not easily change their process. That pointed to a different solution, one upstream.

The Breakthrough: Microstructure through Collaboration

That is when the team expanded its focus to working closely with the steel supplier. Although the material had been produced using a standard method suitable for many applications, Worthington saw an opportunity to collaborate on refining the processing conditions to better meet the unique demands of this more complex application.

Together, Worthington and the steel supplier explored adjustments to the hot strip mill conditions that could drive greater uniformity in the steel's microstructure. These collaborative changes focused on reducing variability and eliminating softer regions that had contributed to earlier failures.

"You're essentially squishing out the inconsistencies. It makes the steel more uniform."

- Paul Pfeifer, Technical Service Manager & Metallurgist

Caption: The iron-carbon phase diagram. Tells us what phases are present based on the temperature.

"You're essentially squishing out the inconsistencies," said Pfeifer. "It makes the steel more uniform."

The results was a steel input with improved consistency and better downstream performance. While the original material has been selected based on its track record and availability, this case reinforced how supplier collaboration can lead to tailored solutions that raise performance for more demanding end uses.

Lab-Driven Confidence: How Testing Guided the Path Forward

Worthington's materials lab validated every step. They conducted:

- Scanning Electron Microscopy (SEM) to evaluate fracture surfaces

- Hardness testing across microstructures

- Optical microscopy to visualize ferrite distribution

- Energy Dispersive Spectroscopy (EDS) to confirm chemical constituents

The data told a clear story. Microstructural inconsistencies remained even after heat treatment, and hardness varied within localized regions across the part.

This lab-driven approach transformed what began as a quality complaint into an engineered solution grounded in data rather than guesswork.

Commercial Follow-Through: A Role for Sales and Support

While the technical investigation was underway, the commercial side stepped in to manage the customer relationship.

One of our Territory Sales Managers joined the team just as the case shifted from diagnosis to resolution. His focus? Communicating consistently, managing expectations, and keeping the partnership strong.

"My role has been maintaining active communication, helping fill any gaps, and being there for the customer whenever they need us," he said.

This was more than a one-program relationship. Worthington had multiple engagements with the customer already, and this challenge tested the trust built over time.

The Advantage of a Domestic Mill Partnership

Worthington had an existing partnership with a domestic steel supplier that had already supported similar applications. With the new demands introduced by this project, the team worked closely with the same supplier to refine how the material was processed in order to better align with updated performance requirements.

Through this collaboration, adjustments were made to optimize the supplier's processing conditions, helping to improve microstructural consistency and meet tighter specifications. By making the domestic option work for a more demanding application, Worthington was able to maintain the benefits of a local supply chain while also improving material performance.

This approach preserved flexibility, responsiveness, and shorter lead times, all while delivering a tailored solution that met the needs of a more complex forming environment.

Why Location Matters: From Mill to Field

The program runs through a regional Worthington site, near the customer's location. That proximity meant faster delivery, greater flexibility, and less risk of supply chain disruptions.

"Geographically, it makes a lot of sense," our Territory Manager noted. "It allows us to reduce transportation time and cost, and it gives the customer a stronger sense of control over their material flow."

In a world where transportation costs, delays, and disruptions are all too common, this move checks every box: quality, speed, reliability, and peace of mind.

Partnership Over Transactions: A Cultural Value

From both perspectives, this case was about more than metallurgy and material movement. It was a demonstration of Worthington's value in action.

"Whether you are talking with our sales team or technical services, what you are going to see is a full partnership," he said. "We stay involved from when the material melts at the mill to when it hits your dock. It is never just a PO and done."

That commitment was evident not only in technical support but also in responsiveness, transparency, and a shared desire to restore the customer's full confidence in their parts.

Lessons for the Industry: Early Engagement, Real Impact

The story for the procurement and operations team is about what happens when supply chains become a strategic partnership.

"Get us involved early," said Pfeifer. "Good samples and fast communication are the key to finding answers."

That mindset is core to how Worthington approaches every challenge. Whether optimizing supply chains, solving metallurgical mysteries, or hanging new ideas to the table, the goal is the same: build value by building trust.

From Fracture to Confidence

Today, the customer is proceeding with the re-engineered material. A full-scale trial was completed through Worthington's processing system. The feedback from testing has been positive. The findings are validated, and the trust is intact.

The real story here is not just about steel. It is about how Worthington brought together metallurgical insight, commercial coordination, and responsive supply chain execution to protect a critical program and deepen a long-term partnership.

While things go wrong in the field, Worthington Steel does not just troubleshoot. We solve. We are committed to driving steel forward together.

About Worthington Steel

Since 1955, Worthington Flat Roll Steel has been delivering top-quality service that enables our customers to do the same for themselves. Our steel processing capabilities serve a variety of markets, including automotive, heavy truck, agriculture, energy, construction, and many others.

Our commitment to our customers' business goes far beyond supplying steel. We provide advanced materials support, buying strategies, supply chain solutions, and the highest level of customer service and collaboration.

If you are interested in learning more about us at Worthington Steel, want to view our capabilities, or have a question that we can help you answer, please explore our website or call us at 1.800.944.3733. We are here to be partners for your manufacturing goals.

With 70 years of experience, we have the resources to help you.